|

||||||

Making Wooden Oil Barrels

The first barrels used for oil were made in the customary fashion of the day (1859) which was the same as for any other liquid requiring a tight container. The staves were prime white oak and the hoops were hickory. The barrel of that time was a work of art. As time went on oak for staves survived, but hickory was soon replaced by iron hoops.

Due to the great demand for barrels brought about by oil, the method of manufacture changed at a rather fast pace and at some point in the 1870's, maybe even earlier, machine methods were well in use to varying degrees. Parts of the barrels were even prefabricated such as the heads and jointed staves.

The process of oil barrel making was more or less as follows:

|

Staves were assembled in a circle and held in position by an iron ring. |

|

|

This infant barrel was steamed in an iron cylinder, thus softening the oak wood. |

|

|

The staves were bent into shape and drawn together by a circle of wire rope run by an engine. An iron hoop was slipped over the upper end to hold the staves in position. |

|

|

The barrel was fired inside by burning shavings or some other easily fired material. This rendered the curvature of the staves permanent. |

|

|

Thick temporary iron hoops were slipped over the barrel and drawn toward the bulge by machinery. |

|

|

The rough ends of the staves were pared off in a lathe. Grooves for the heads were cut into the barrel. This groove is called a croze. |

|

|

Iron hoops (usually six) were driven over the barrel by a steam hammer. The top hoop is the chime hoop and those nearest the bulge are bilge hoops. |

|

|

Hot glue, glycerin or soluble glass was poured into the barrel via the bung and the barrels were rotated. The purpose was to coat the interior with a continuous skin to help make the barrel tight. Excess glue was drained off through the bung. Judicious use of hot air forced into the barrel helped to dry the glue. Glue was introduced into the coopering process in 1866. |

The above process was described by Sir Boverton Redwood in 1886 but doubtless had been applied long before then. It was the method of manufacture for refinery and export barrels, a better grade than crude oil barrels.

Barrels destined to hold refined products like naphtha or benzine were given extra care in their manufacturing (as per above). They were painted blue except for the heads which were white. This distinguished them from barrels made (or used) for crude oil. Refined oil barrels which were returned empty were cleaned by revolving wire brushes, steamed out, reglued and repaired (according to Redwood, 1913).

The dimensions of a wooden oil barrel are hard to find in the literature because of the many variations in sizes of those made in the 1860's and maybe later. Still, it is hard to understand how this important information escaped the early authors of the 1860's and even later. In 1951 Mr. A.C. Brown of the Drake Well Museum staff measured a barrel found in the Crew-Levick Refinery and found it to be 33 1/4 inches long as measured on the stave, 31 1/2" between barrel heads and 19 1/2" diameter of the heads (reported by Hardwicke, 1958). These dimensions do not allow calculation of volume.

Time and bulk shipping has long done away with oil barrels. For years the author has looked for a true wooden oil barrel that had once held oil, but so far to no avail. Old wooden separators and stock tanks are still around in the abandoned oilfields of NW Pennsylvania, but the wooden oil barrels have apparently disappeared. This seems incredible in view of the many tens of thousands of them that were so common on a daily basis in the early Pennsylvania oil region.

According to Hardwicke (1958), T.J. Garin, then curator of the Drake Well Memorial Park in Titusville, Pa., sought wooden oil barrels to be used in a 1951 documentary film Evolution of the Oil Industry. There were none in sight in this pioneer oil belt. Finally some old barrels were found somewhere on the premises of the old Crew-Levick Company refinery in East Titusville. This means that fifty years ago (and long before) the oil barrels were gone except those that might be in forgotten crannies.

|

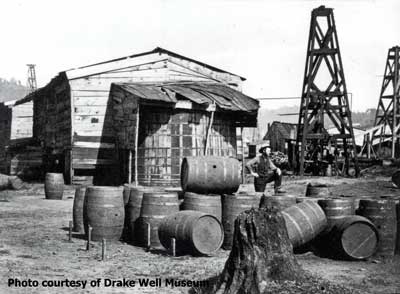

Wooden barrels and stock tanks were a common sight around oil wells in the 1860's-70's. This photograph is of the Egbert & Hyde farm in the Petroleum Centre area of Oil Creek Valley, ca. 1864. These fine six-hoop barrels clearly show the bung in the center of the bilge (bulge) sector. Production of the nearby well has apparently declined and leveled off judging from the single (but large) stock tank and the low number of empty barrels. |

![]()

| © 2004, Samuel T. Pees all rights reserved |

|