|

||||||

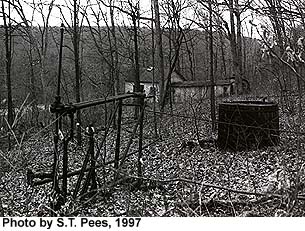

The Pump Jack

|

The elements of a simple pumping jack. This Oklahoma-type jack was popular in many oilfields including those in the Appalachian Basin. They were operated by a central power to which they were connected via rod lines. This model was advertised by Jarecki Manufacturing Company, Erie, Pennsylvania (no longer present). Pumpers sometimes made their own jacks out of salvaged parts in the field. Variations were common in these homemade cases, but they got the oil out. |

There are a lot of jacks dotting the Pennsylvania oil belt and in other fields where shallow stripper production prevails. In fact, there are several generations of these devices, many still in their original place next to a well head. Not all of them stand upright any longer. Wooden bases and beams (if wood) may have rotted allowing the other parts to fall to the forest floor. Some kinds were entirely made of timber except for bolts. Occasionally one will come across a jack "bone yard" where all types of them are stored. There are many styles of pump jacks.

It's an uplifting experience to see them pumping, especially if the jack is connected to a distant power by its rod line. Jacks that are installed nowadays often use an electric motor which starts and stops by a timer. There are small gasoline engines for this purpose too. Pumping jacks are not run continuously. Some are worked only two or three times a week. During the quiet periods, oil and salt water percolate from the formation into the hole, filling it to a level for pumping.

Operators watch the posted price of crude oil. When it gets too low, they only pump oil in enough quantity to maintain the lease. Serious pumping (and maybe more drilling) occurs when the price is right. We are not talking of great volume here. A settled stripper well in Pennsylvania may lift only a half barrel per week but some are better, especially if repressuring of the oil reservoir is carried out. A settled well can carry on for 40 to 80 or more years (a few have already waved good-by to 100 years a couple of decades ago). A new well after hydrofracture may pump several hundred barrels over its flush period (first 90 days), but that is maximum, it settles back quickly.

|

This picture shows some of the elements of a field that was produced by a power (it is in the building in the background). The pump jack in the foreground is still hooked to the power by a rod line. A wooden separator tank (center right) received the oil and allowed it to float on the saltwater. The oil from the seperator was gravity fed by a pipe down to a stock tank (not seen) where it was picked up for the refinery. This well is abandoned, but some oil may still be produced here. |

![]()

| © 2004, Samuel T. Pees all rights reserved |

|