|

||||||

Keystone Driller

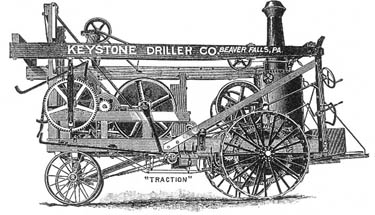

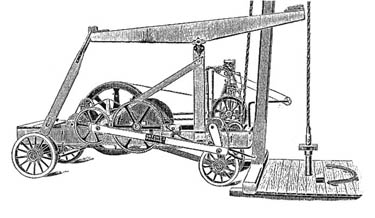

As previously mentioned in the chapter devoted to steam engines, in 1878 Robert M. Downie of Butler County, Pennsylvania, designed a wheel-mounted cable tool rig that held a vertical boiler, vertical steam engine and the operating or hoisting wheels. The engine operated a spring pole, the butt end of which was anchored to the ground a short distance behind the drill wagon. The fulcrum of the spring pole arrangement was on the rear of the wagon. A tripod served as derrick or mast and the base of the poles were stuck in the ground. This device is pictured in the aforementioned chapter.

R.M. Downie and his brother called this and subsequent rigs Keystone (a Downie trade name) and the first ones (described above) were built in Pittsburgh by the William Velts Company (Brantly, 1971). About a half-dozen were sold for the drilling of water wells. Later the Keystone Driller Company was established in Beaver Falls, Pennsylvania.

Downie was soon able to substitute a "stiff beam" on the wagon for the spring pole (1880). He also used a double working beam in the 1880's and went on to mount an A-frame folding-type ladder mast and braces on the wagon in 1892 or slightly before. Previously, in 1888, Downie had turned out a self-propelled machine using his earlier stiff beam wheel-mounted apparatus. This early traction machine ran on steam power which was already on the machine. The large steel wheels had lump cleats at first, but later traction models of 1906 (double beam, A-frame mast) had diagonal cleats on the pair of rear wheels. By 1920 Keystone was the first to put solid rubber tires on a portable rig, at least on the front wheels. Keystone was also among the first to put crawler tractor wheels on a portable rig (early 1920's). Of course, gasoline engines were already in general use.

This sequence of Downie inventions and models from 1878 to 1892, only 14 years, was remarkable. Keystone, by the ingenuity of R.M. Downie, achieved a high rank among the competitive manufacturers of portable cable tool rigs.

Perhaps the most important concept that was put into use by Downie was the spudder drill rig of 1892 which enabled the tools to drill all the way to total depth without the need for a clamp and a temper screw. The screw limited the amount of hole drilled at a given time to the screw's length (usually about 4 to 6 ft.) except for interruptions needed for bailing out the cuttings.

According to the API publication, History of Petroleum Engineering, 1961, the spudding manner of drilling was achieved as follows: "---the drilling line is carried over a pulley just above the main drilling reel and then in a horizontal plane to another pulley, called the "spudding pulley," which is attached to a beam that hinges at the back of the machine. The forward end of the beam holding the spudding sheave is attached to a pitman that raises and lowers the spudding sheave. The drilling line goes under the spudding sheave, then vertically to another sheave at the top of the mast, and from there into the hole being drilled. Drilling motion is obtained by the up-and-down travel of the spudding sheave on the drilling line."

Downie, as Keystone, also used the regular walking beam motion and temper screw on some of the early Keystone rigs. However, he commercially pioneered the spudder-type drilling practice. It finally went into general use in the 1920's - 30's.

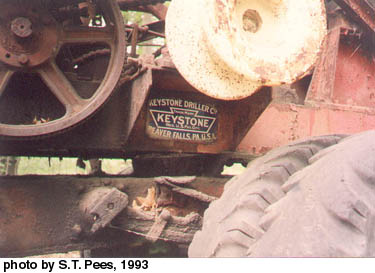

The author has Keystone catalogs and company literature. A considerable number of portable rig models were put out by that company. Old abandoned Keystone drillers have been seen by the author inthe oilfields.

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

|||||

|

![]()

| © 2004, Samuel T. Pees all rights reserved |

|