|

||||||

Bit

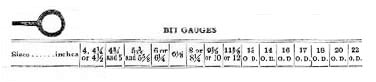

In 1913 Oilwell was listing regular drilling bits for holes ranging in diameter from 4 to 22 inches. Bits for the smaller hole sizes, 4 - 4 1/4 - 4 1/2 inches, were 3 feet 6 inches to 5 feet long.

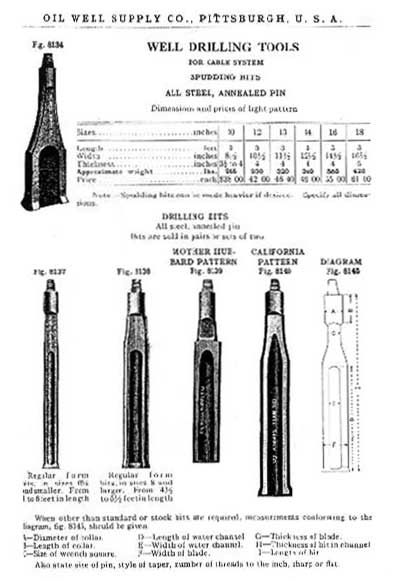

There are three main types of bits: a spudding bit was used to drill a wide hole from the surface for the casing or conductor pipe and a regular bit was used to drill the hole the rest of the way to total depth. A third type, the reamer bit, was used occasionally to keep the hole diameter at the proper gage.

The spudding bit was squat and heavy and was not run from the walking beam. The casing hole couldn't be drilled with the regular tool string because there wasn't enough room to accommodate the string until the hole was deeper (60 feet plus). Regardless of motive, the casing hole had to be done by the spudding method. The casing or conductor hole was drilled by a cable worked from a wristpin on the crank of the band wheel shaft and held by a pulley in the crown block at the top of the derrick, then fed down to the auger stem which was fastened onto the bit. The blows from this bit and stem smashed a shallow hole (50-200 feet or more) under the guidance of the driller.

The regular drilling bit was originally called a center bit and is about 3 1/2 to 5 1/2 feet long with a wedge or blunt chisel-like cutting edge. Notable features of the regular bits are the water channels (lengthwise grooves or courses) which probably originated in the 1860's or 70's. The water channels varied in length and width in the various models. A spudding bit had a very wide channel in its lower part.

Sometimes the hole may not be at gauge, especially if the regular drilling bit has worn awkwardly. In this case a special reamer bit was used to ensure the proper hole diameter.

Bits had to be dressed by the toolie at the forge on the derrick floor. In the early 1860's the bit may have drilled only 2 or 3 feet, usually a little more, before it was pulled out of the hole for dressing. The drilling rate depends on the hardness of the strata and on the effect of accumulated cuttings. After pulling the bit, the hole was cleaned out with a bailer. While the driller bailed, the assistant dressed and gaged the bit.

Cable tool drilling was usually conducted in areas where hard sedimentary rock strata prevail such as the Paleozoic beds of the Appalachian Basin, but it was not limited to eastern United States. Cable tools were also used in California and many other states. They were not satisfactory along the Gulf Coastal Plain because the strata are too soft there.

|

|||||

|

|||||

|

|||||

|

![]()

| © 2004, Samuel T. Pees all rights reserved |

|